Technology

Most modern technology and experience

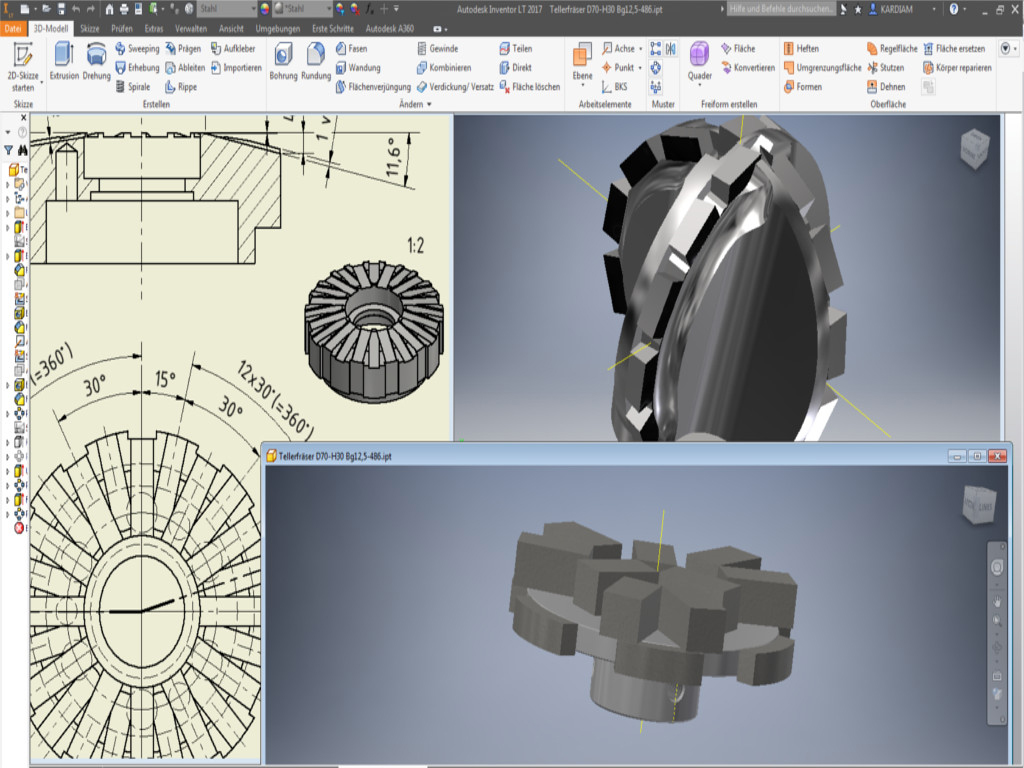

Already during the development of our tools, we rely on a solid construction using the latest 3D design software (Inventor).

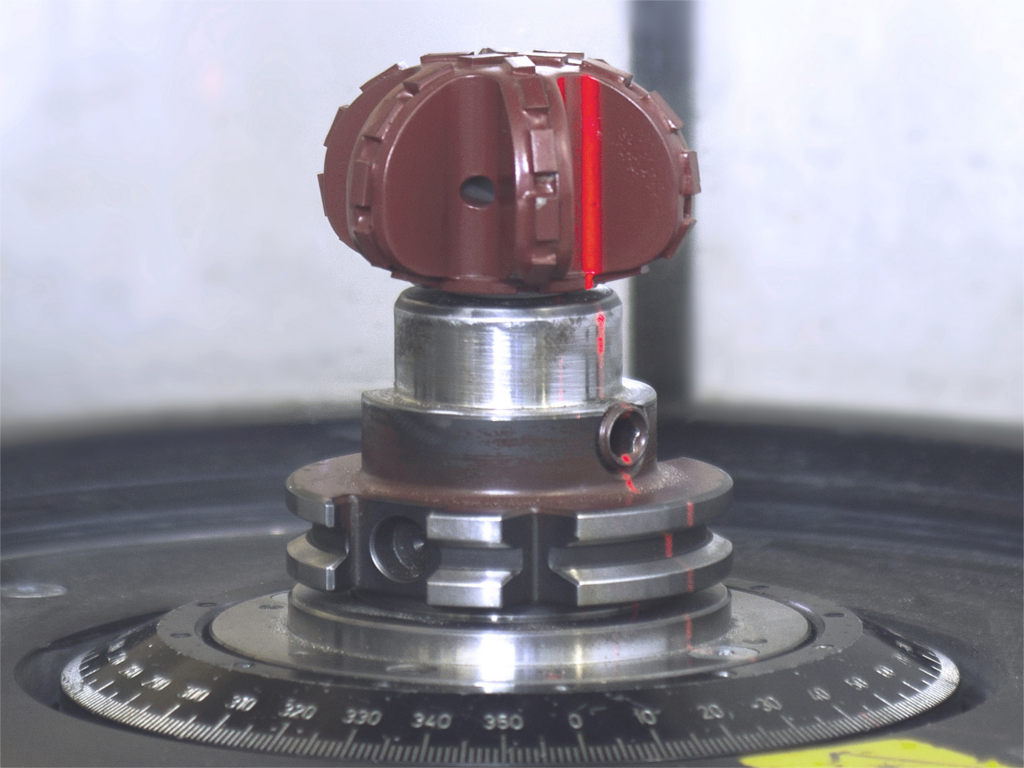

Using a modern machinery (for example a 5-axis milling center) the complex base bodies are produced accurately and according to the existing 3D models.

Equipping the body requires a lot of skill and is implemented by our specially trained and experienced staff.

We place particular importance on the finishing of our products. The reworking of the solder joints and the electronically controlled verification of massiveness and subsequent balancing of the tools are self-evident for us. In addition to the protective coating, our tools are marked with an engraving to assure quality. After a final inspection, the tool is ready for shipment.

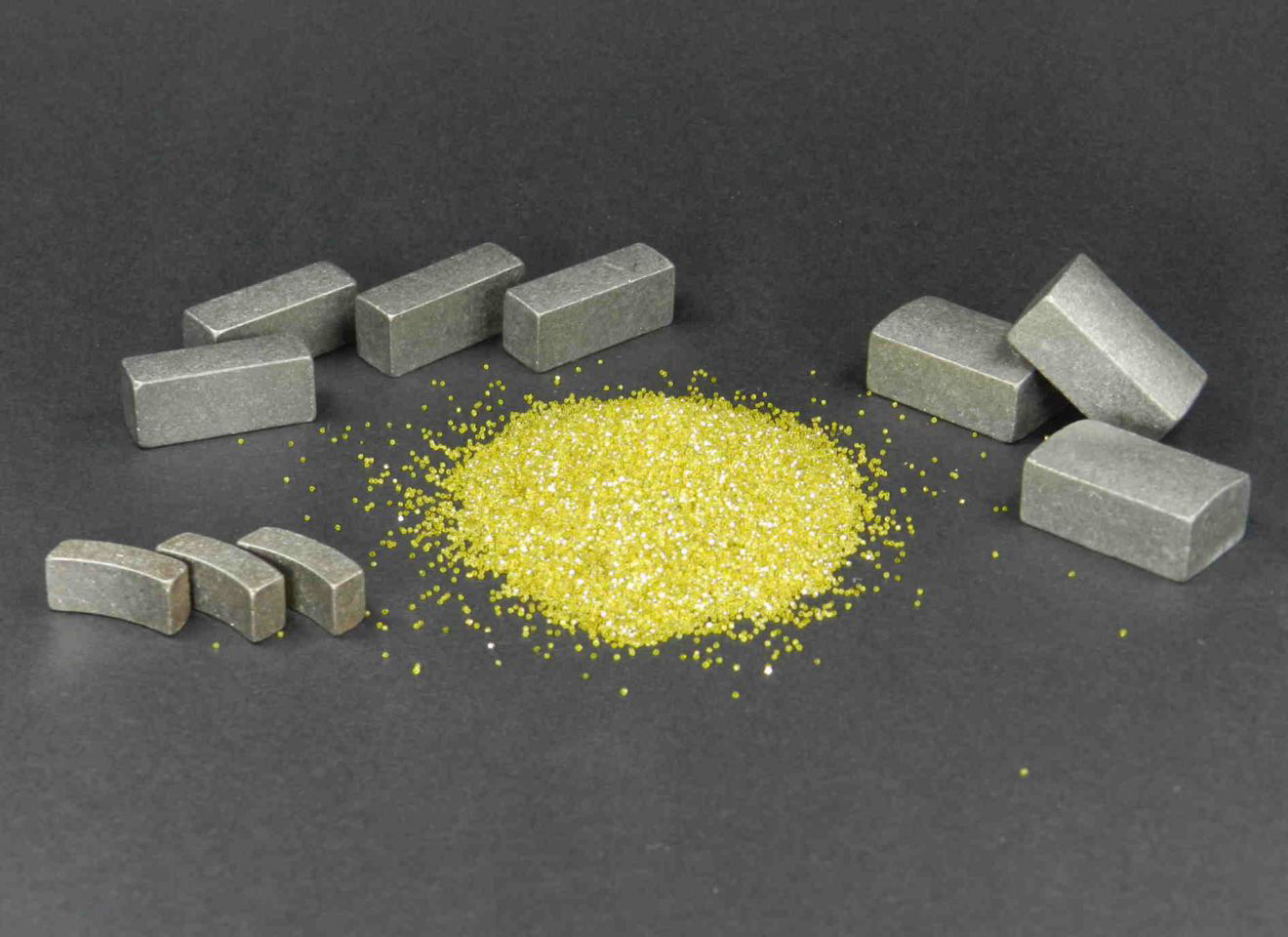

Many years of experience in segment production strengthen our success:

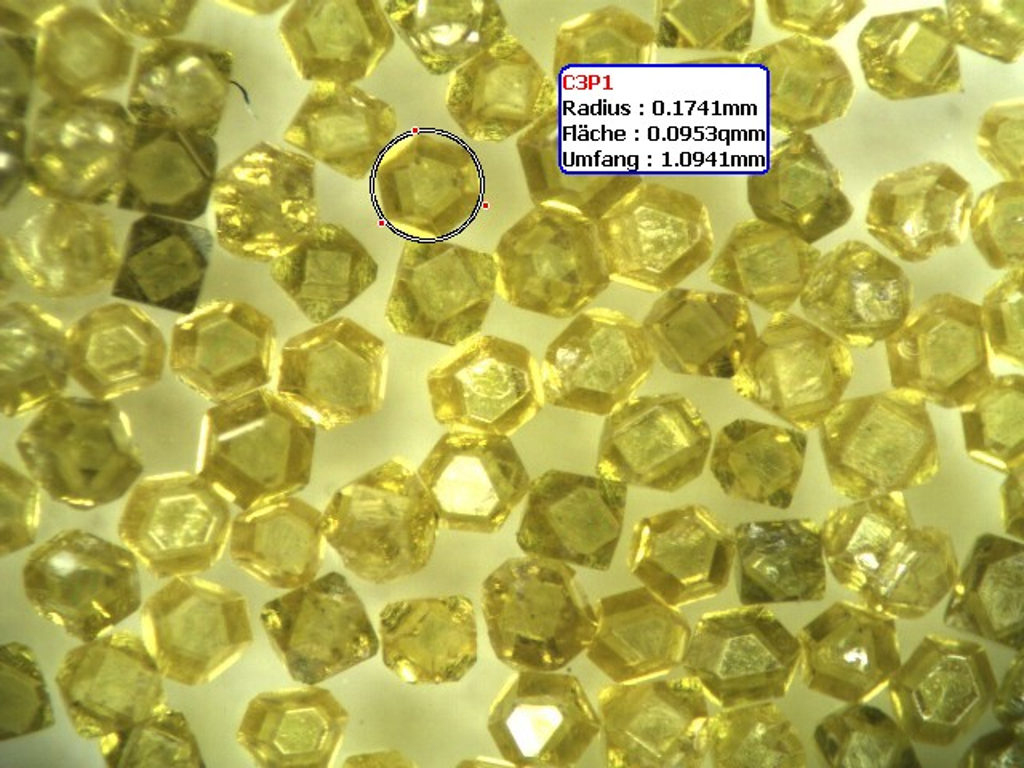

The diamond sinter metal powder mixture is pre-pressed into blanks using cold presses, whereby special segment inserts or segment stresses (such as sandwich type, neutral zones, particularly concentrated areas) can be taken into account and enable corresponding optimization. Fully automatic and electronically controlled sintering presses guarantee high and consistent quality in segment production.

A fully automatic high-frequency soldering system for diamond saw blades works perfectly and is suitable for the highest demands. The cutting disc dressing and sharpening machine ensures that the saw blade runs true and that the diamond protrudes in the segment. Another high-frequency soldering system for diamond drill bits enables us to place them extremely precisely by means of an opto-electronic measurement of both the segments and the base body. In addition to the production of new tools, the refitting and repairing of the different tools is important to us in terms of cost savings for our customers and is realized with the appropriate care.

Cooperation

Our great success is, among other things, based on the intensive cooperation between our customers and users who communicate practical needs to us. Together with machine manufacturers (e.g. sewer rehabilitation robots) and research institutes such as universities or technical research departments, our own design and development department develop solutions as wanted by customers and users.1